The Importance of Mastering Samples

There are many reasons for making samples, with some being more obvious than others. Since creating samples can be just as much work as doing an actual project – and cost you time and money – it’s critical to make the process worth your while. Read on for tips to cut costs and simplify the process.

Build Your Arsenal

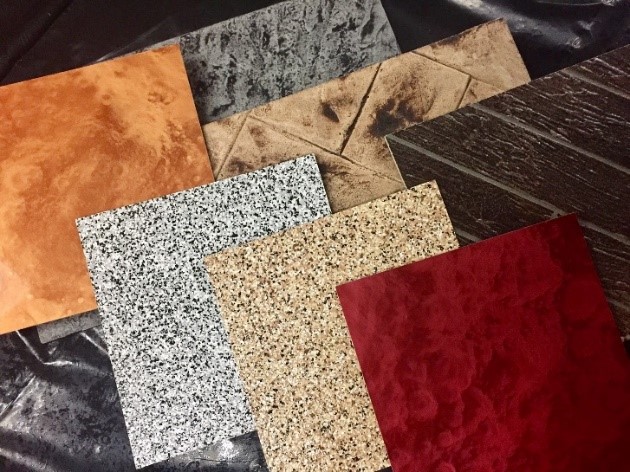

When it comes to concrete overlays and toppings, there are so many options at your disposal. It is a good idea to have multiple samples on hand so the customer has a variety to choose from. This adds value and versatility to your company and increases the customer’s confidence in your capabilities. However, this doesn’t mean you need to have a hundred different samples to show each color, finish and texture. With so many colors and products available, it would be impossible to have a sample for every option, and it would be difficult to transport. Instead, consider making one sample of each application, style and texture. Utilize color charts to show that the same application can be done with multiple colors. As you land more projects, you will learn which colors are more popular than others. This will help you determine which samples and colors to display on the next project.

Utilize Excess Materials

This brings me to my next point: use your excess materials to make more samples. Making a sample is much easier if you don’t have to carve out additional time and money to create them. If you are on a project and have leftover material, it is a great idea to put that material down on a sample board rather than disposing of it. It is also a great way to get the finished appearance approved for that same project. For example, if you are doing a stamp overlay on a driveway and you get to the end of the application, put the rest of your mix on a board and stamp it with the same texture as the project. You can then apply the colors that were chosen and get the customer to sign off on an approval prior to putting down the colors on the actual project. That sample can also be cut down into multiple samples, and you can apply different color schemes and provide more options. This will instill confidence in yourself and the customer that they will be getting what they want and that you will be able to replicate the sample exactly. The same thing goes with the sealer. You can apply the sealer to the sample and the customer will see how it will enhance the color so there are no surprises when it is time to collect a check. When all is said and done, you have another sample to add to your arsenal at no additional expense.

Honing Your Technique

With each sample you create, you will only get better at what you are doing. Repetition is key in mastering your application techniques. If you offer a wide variety of applications, it can be difficult at first to get the hang of which colors look good with each other and how to achieve certain effects. The coloring techniques of a stamped texture are dramatically different than staining a smooth surface. When applying effects to metallic finishes, timing can be crucial. The more samples you make the more familiar and comfortable you will become with these techniques. A lot of times you will develop your own style and that is when you start to stand out from the competition, being able to offer master artistry to your projects in creating unique looks that only you can achieve.

Close More Bids and Increase Sales

Having finished sample boards at your disposal is a fantastic way to seal the deal when proposing a bid. In most cases, a customer already has certain expectations or an idea of what it is they want. Some bids may be very specific depending on the situation, while others might allow some wiggle room for multiple options. If you can replicate what it is they want so that they can see and touch it, you are more likely to get the project. Being able to physically show the customer what the actual finished product will look like again builds confidence that you can produce what they want.

Upsell Projects

If you are bidding on a basic low-cost application, in many cases you will be able to upsell that project. You will want to have finished samples of different applications varying in cost and appearance on hand. This will get the customer thinking about the possibilities of a high-end finish. I recommend creating some bare bones, basic and affordable applications; some high-end outrageous options, as well as some right in the middle.

Often, you will find a customer originally just wanted a simple patch for their concrete, but once they see other decorative options and pricing, they will consider switching gears. If the high-end options are out of their price range, they might want to settle with the middle ground options. Now you are making the customer happy by exceeding their expectations as well as increasing your sales for that project.

In other cases, a customer hasn’t decided what it is they want, or they are relying on your expertise for guidance. With so many texturing options, styles and colors available, you might be wondering how you present some options without going broke in the sample-making process. Plus, there are budgetary restrictions on the customer’s side. You don’t want to go through the trouble of making high-end samples, only to be told your customer can’t afford them. This is where the arsenal comes in handy. Create your samples as you do your projects and you will end up with many different samples of all sorts of variety.

Make it Personal

It’s important to know your customers and their needs.. If they are very specific about their wants, that narrows down many variables and makes creating a sample relatively easy. Are you presenting samples to an architect or project developer? Or are you working with a retail outlet or homeowner?

When creating industrial or structural samples, it is a good idea to show the multiple steps or layers involved with the process. These are usually specific applications with detailed specifications or blueprints, and they usually want to see how the product is being applied and exactly what it is that is being presented. These samples typically have all elements of the system exposed to see each step of the process – not necessarily concentrating on the finished look alone.

When creating more decorative samples, keep them clean. You want to have clean edges and prevent any material from getting on the back of the sample. Keep them presentable, as they also show your neatness. Masking the back and edges of your samples might take a little extra time, but the effort makes all the difference in the world. Some people create frames or borders for their samples to disguise the edges and clean up the look, but this might cause them to be too bulky or heavy to transport. These might be more suitable for displaying in a showroom or on a wall in your front office.

Lastly, be sure to label your samples with which products and colors you used, so you can reference them later and replicate those exact looks again and again.